3D printing – Silicone – Moldmaking

Early this summer while watering the garden I found the small rubber washer missing from our hose nozzle and, as the water sprung forth from the leaky joint all over myself, an idea sprung into my mind. I had for a while been considering the use of 3D printing not for an end product or finished part, but as a way to make more traditional industrial processes accessible to the home shop and backyard projects. Having done an internship at a plant that produces composite silicone seals I am somewhat familiar with the process of turning raw silicone into finished parts. So, I thought this might be a good place to start experimenting. One pandemic, a stimulus check, a visit to the Creality online store, and several months of delayed shipping later, here I am ready to finally make my 35 cent washer.

The process in an industrial setting is relatively simple – raw silicone is mixed with additives, following a recipe that will produce some desired hardness, color, heat-resistance, durability, etc. It is then rolled into sheets, where it is usually combined with a special cloth backing for strength. The sheets are cut into shapes, and these shapes laid into molds, layer upon layer, before being closed up and cured. Upon removal from the mold they are cleaned up, inspected, and shipped to the customer.

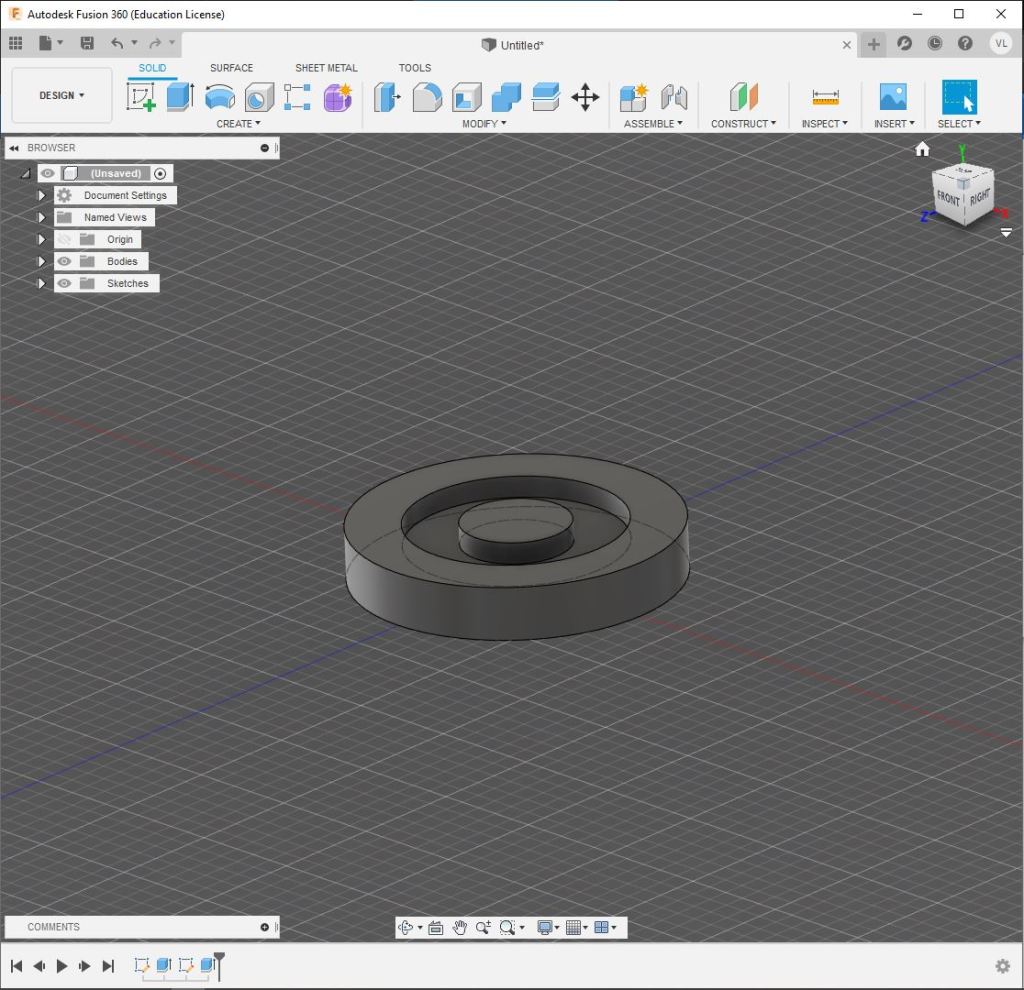

I was surprised at how much hand work was involved! Nearly all of the parts we produced were essentially handmade, with dozens of small silicone puzzle pieces arranged just so and pressed into complex concavities carefully carved into blocks of steel. It takes more than a bit of patience and skill to do well, and lacking these my experiments here will begin at the most basic level. I began with designing a simple mold for a washer. 40 minutes later it was hot off the print bed and nearly ready to accept some silicone.

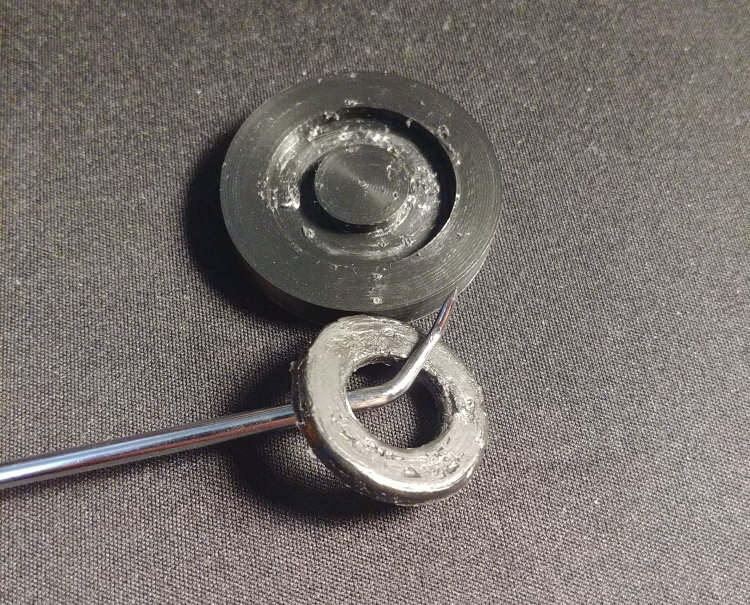

Molds must be treated before use with a mold-release agent to prevent the part from sticking, just like greasing a cake pan. Depending on the material being molded this is usually a waxy or oily film applied from a spray can or rubbed on by hand. Shamefully, I don’t have any proper mold release in the garage, but I figured a light layer of silicone PTFE (Teflon) grease would do the trick. I worked a bit of Super Lube over the mold, down into the recessed area, and it was ready use.

I have seen some 3D printed molds being used for casting silicone before, but these are usually cast with some sort of two part food-grade or model making silicone that is mixed and poured into a mold. This is somewhat messy, creates a lot of waste, and requires material that might not be available locally. But there’s another product that I think may be easier to use, and that many people might have at hand – RTV Silicone. This is a product that comes in a tube at any hardware store or auto parts store, used for making seals and gaskets between parts. It dries, or vulcanizes, at room temperature (at last the meaning of “RTV” becomes evident – room temperature vulcanization) and is available in varying degrees of hardness and temperature resistance. I had some high-temp oil resistant RTV on hand, so into the mold it went.

After smoothing and evening out the silicone by wiping a piece of cardboard across the top, it was left overnight to cure. The next morning the washer was removed with little trouble. It was stuck to the mold in one place where evidently I didn’t apply the mold release well enough, but aside from that one spot the Super Lube performed admirably.

The surface finish wasn’t perfect, likely because of air bubbles between the silicone and the mold, but I think this proves well enough that the process works. I’ve already made a list of several things I’d like to try differently in the future:

- Use wood filler and spray paint to create a smoother mold surface

- Use a brush to apply the mold release, working it into small voids and gaps

- Try using regular car wax as a mold release

- Use a two part mold to squeeze out bubbles and get a more uniform finish on all sides of the part

- Experiment with additives, such as corn starch or fine nylon mesh, to improve the final properties of the part.

- Combine this with other 3d printed parts to overmold a layer of silicone onto tool handles, RC car tires, etc.